Test Systems

Unit testers and systems for Aerospace and other applications

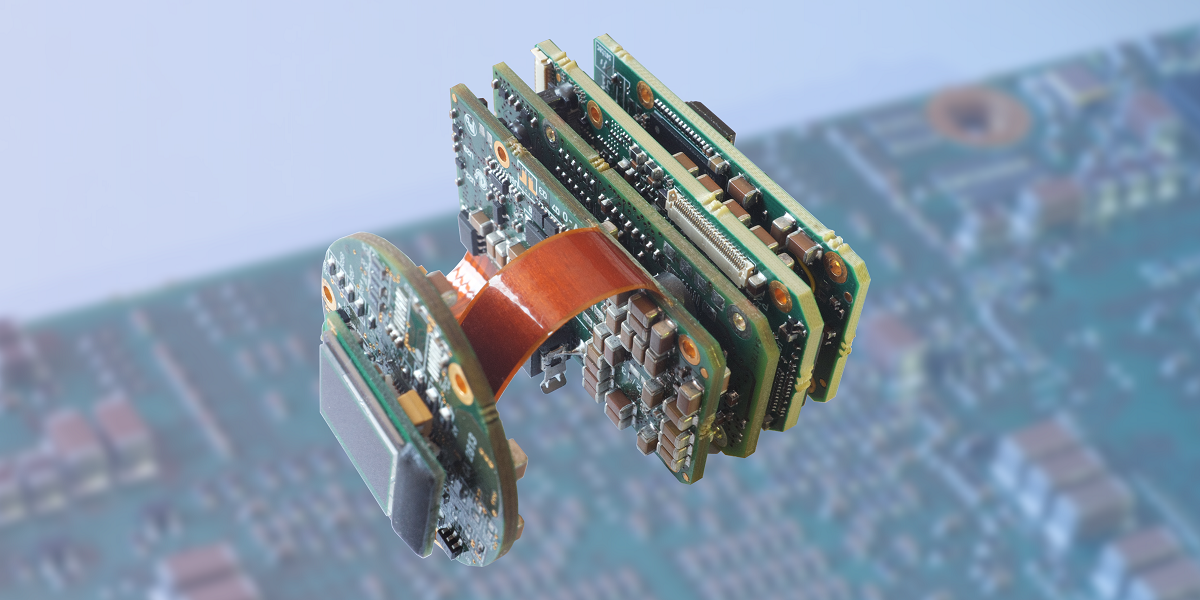

Saitec test system design continuously looks for the best combination between high modularity and high specialized HW and SW architectures. On one hand, the design phase is finalized to meet our customers’ requirements, which usually ask for highly customized specifics; on the other hand, this phase has to follow already developed HW and SW modules, ensuring the same operations, especially in terms of MMI. This guarantees an economic advantage for the customer not only at the purchase moment, but also in terms of training, re-configurability on different programs or on different phases of the same program.

Due to the modular design and manufacturing approach, some units are made as stand-alone modules, such as Saitec PDU - Power Distribution Unit.

Attention to details

Test systems realized by Saitec are involved in a continuous improvement plan based on the information collection and analysis. Data and information registered in the technical documents used by the assistance and maintenance service, together with customers observations and suggestions, are fundamental in order to establish and implement the corrective actions to improve products quality. This process leads to the attention for some details, such as the supporting embrasures for connectors protection, the rings for guiding the cables realized to avoid different interferences, buttons and switches protected to avoid unexpected drive, tool trey, user manual and other documents.

Quality certified

Saitec Quality Management System is certified according to the Aerospace certification EN9100:2018 and all the processes involved in the test systems development realized by Saitec are controlled and certified according to this standard. The validation activity is carried out according to the system requirements plan, in order to guarantee the certification of product conformity to requirements.

Safety

Saitec test systems are CE certified and conformed to electromagnetic compatibility (EMC) required according to EN 61326-1 and EN-61010-1 standards, applicable to measure, control and lab use of low voltage systems. Saitec certifies its test systems in compliance with (CE) n.1907/2006 standard, known as “REACH” (Registration, Evaluation, Authorisation and restriction of Chemicals). This, together with the attention to the ergonomics of the operating station, represents the guarantee of Saitec-s commitment to the protection of health and safety, both for products and people.